GIAP's Conventional Acetic Acid technology sized up to 150 ktpa

GIAP's Conventional Acetic Acid technology

Acetic Acid technology sized up to 150 ktpa

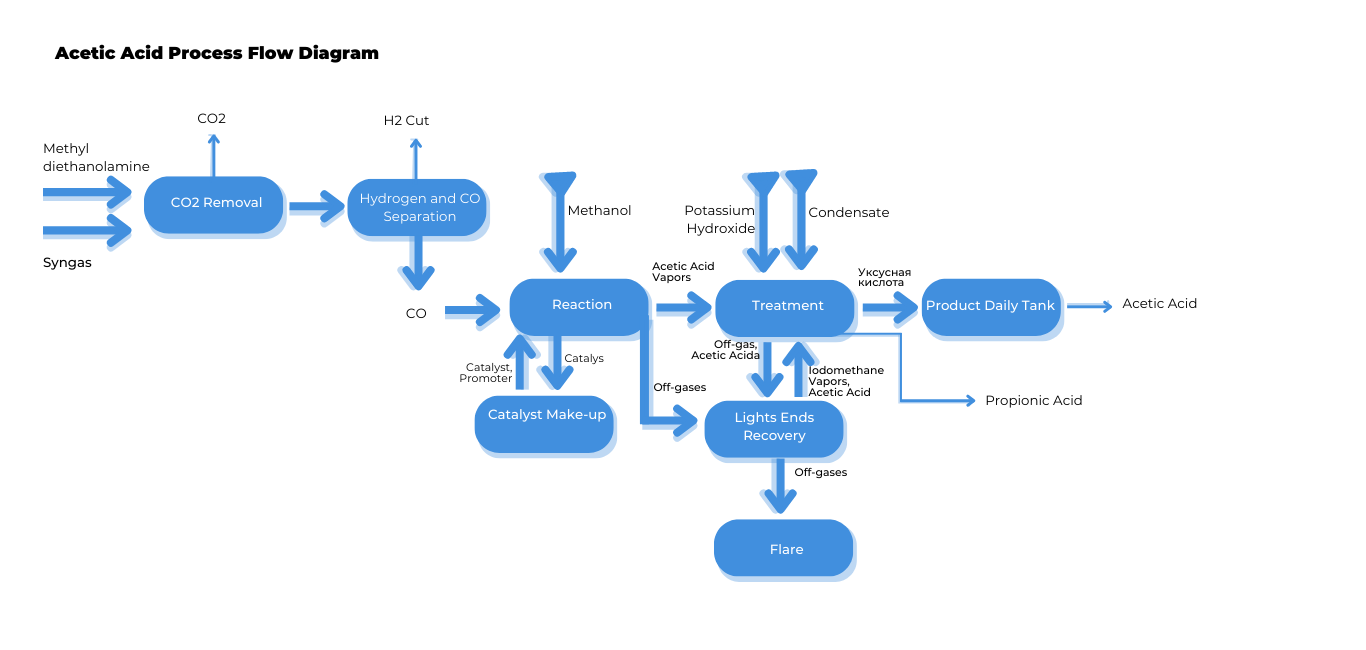

The acetic acid technology is based on methanol carbonylation using a rhodium based catalyst system and includes carbon oxide production from syngas and the acetic acid production process itself.

The acetic acid production technology consists of the following stages:

1. Syngas treatment to remove carbon dioxide.

2. Cryogenic carbon oxide extraction unit.

3. Flare.

4. Synthesis.

5. Distillation.

6. Light ends recovery.

7. Catalyst make-up and regeneration, promoter make-up.

8. Daily production warehouse.

9. Flare

Key benefits of the technology:

1. High-quality end product.

2. Usage of available feedstock – methanol.

3. Campaign implemented to prevent environmental pollution.

4. High rate of methanol conversion to acetic acid (nearly 100%).

5. Improved process reliability and sustainability.