GIAP’s SMR ME Methanol Technology rated up to 3500 tpd

GIAP’s SMR ME Methanol Technology

Methanol Technology rated up to 3500 tpd

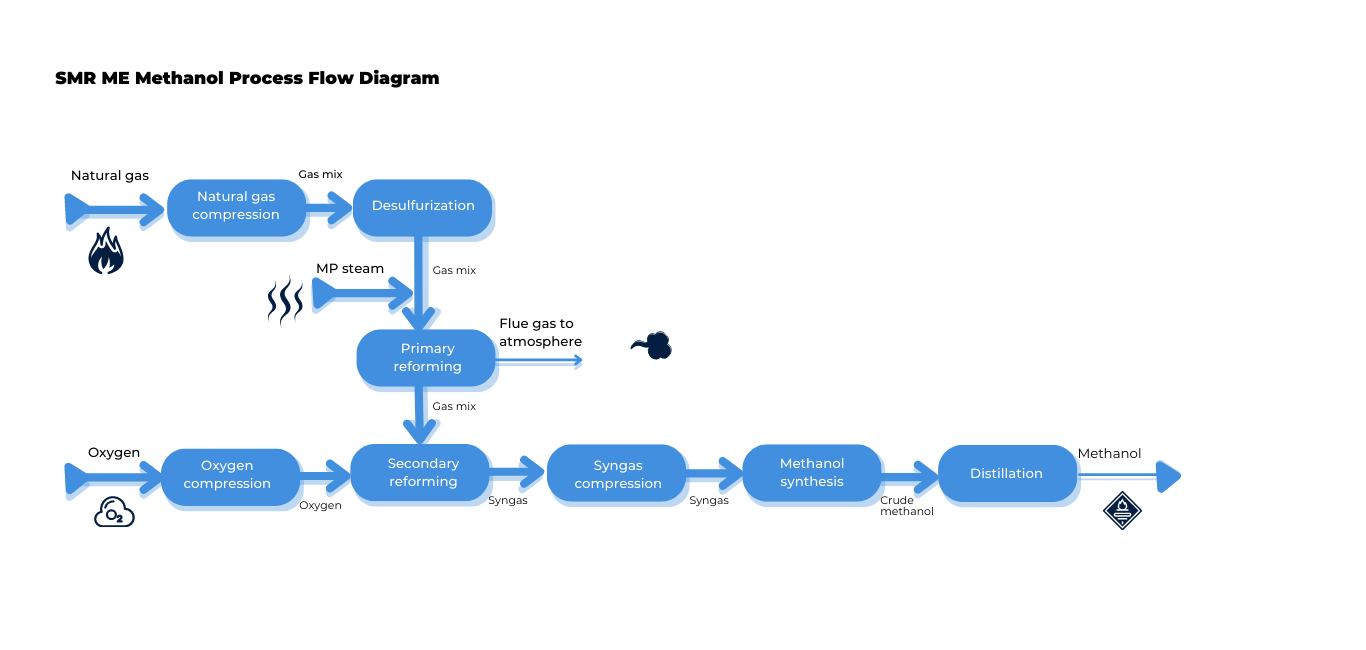

GIAP's unique SMR ME technology employs steam reforming to produce syngas. Methanol production is realized using energy-saving solutions with integral steam, demineralized and deaerated water generation facilities, waste heat recovery from process streams and process condensate utilization for process needs.

The reforming stage is fueled by combustible production wastes (blowdown gases and flash gases from methanol synthesis stage, methanol vapors and highly volatile components from predistillation and main distillation stages).

Typical capacities for SMR ME technology: 1500, 2000, 2500, and 3000 tpd.

GIAP’s SMR ME methanol technology includes the following stages:

1) Natural gas compression;

2) Natural gas desulfurization;

3) Primary reforming;

4) Secondary reforming;

5) Syngas compression;

6) Methanol synthesis;

7) Distillation.